Audi Repair Shop Doylestown

Call 267 279 9477 to schedule a appointment

The idea-people aren’t finished trying to revolutionize the skateboard electric vehicle platform and in-wheel motors. Israeli startup Ree is doing both. It’s toiled on the idea for seven years, putting together the 3D-printed Flatformer concept heavy truck chassis with Hino for last year’s Tokyo Motor Show. Now the tech firm has partnered with Tier 1 OEM supplier KYB, a multibillion-dollar Japanese conglomerate specializing in active and semi-active suspension systems and owner of the world’s largest factory producing shock absorbers. The challenge ahead of this “strategic partnership to develop suspension capabilities for future electric vehicle (EV) platforms” will be clear after we explain how Ree’s system works.

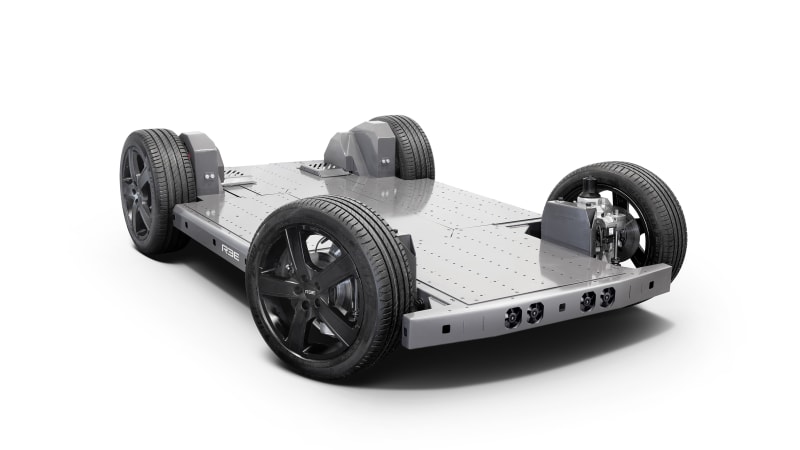

The easy part is the Reeboard, the plank that contains the batteries. Last summer, Ree’s digital presentations showed a Reeboard 185 inches long, with a 110.6-inch wheelbase — a near carbon copy of the Tesla Model 3‘s length, with a wheelbase 2.6 inches shorter. This is where all the batteries go, Ree leaving room inside to sandwich modules from tip to tip.

The marvel is contained inside the Reecorner module that connects the platform to the wheels. Starting at the platform and working out to the wheel, a far as we can tell from an image in the Ree promotional deck, a C-shaped steering bracket attaches to an axle stub emerging from a motor between the bracket and platform. If this is accurate, it would keep the motor from becoming unsprung weight like a true hub motor. A small reduction gear and coupling sit inside the bracket’s open space. The bracket and gearing are attached to a cylindrical housing containing a small coilover damper that Ree says is a “novel active suspension with semi-active capabilities.” Clamps on the other side of the suspension housing attach to the brake rotor and the hub that mounts the wheel.

This is a wild solution, all the more so when a video shows the entire assembly from the steering clamp to the hub rotating with the wheel, including the brake caliper since there’s no stationary mount to bolt it to. Tuning an active or semi-active suspension that rotates at wheel speed to counter primarily vertical forces must make for phenomenal math and programming. However, in the video below, certain parts of the assembly behind the wheel face are stationary.

The Reeboard employs steering- and braking-by-wire. There are also diagnostic modules in the Reecorner to alert users of problems. The startup says its solution cuts weight by 33% compared to a typical electric car platform, would improve space utilization by 67% in an autonomous last-mile van. For more traditional vehicles, Ree’s presentations last year hypothesized a sports car that could do 0-60 mph in 2.6 seconds, a pickup with 720 horsepower, 14,741 pound-feet of torque, and a 1,874-pound payload capacity, a minivan with four rows and a height-leveling suspension, and a three-row sedan with a 400-mile range.

Ree claims that in addition to the “complete design freedom and cost-effective, scalable solutions” of the Reeboard and Reecorner, maintenance is a cinch. Since all the important transportation bits are hung at the corners, a mechanic would only need to replace the entire Reecorner module to get a vehicle back on the road, a task the company’s tech chief says can be done in 15 minutes. We hope someone takes Ree up on this, because we can’t wait to take it for a spin.

Related Video:

from Autoblog https://ift.tt/2M3cxBn