Audi Repair Shop Doylestown

Call 267 279 9477 to schedule a appointment

Much remains unknown about how exactly Ford plans to fast-track production of ventilators and powered air-purifying respirators with two established medical device makers as it hurries to join the fight against the expanding coronavirus outbreak. But it’s likely that the automaker will leverage its decades spent tinkering with 3D printing.

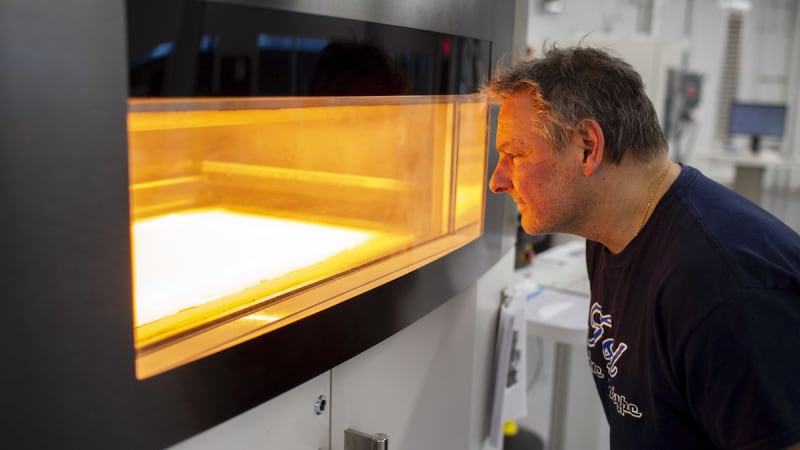

In its announcement Tuesday, Ford made it clear that the technology is central to its plans to assemble more than 100,000 protective plastic face shield masks per week from a subsidiary in suburban Detroit. The company also said it would use 3D printing at its Advanced Manufacturing Center in Redford, Mich., to make components and sub-assemblies for use in personal protective equipment. Ford opened the $45 million facility in 2018; at the time, it said it had 23 3D printers and was working with 10 3D printing companies.

Included in Tuesday’s announcement was a plan to partner with 3M to boost production capacity by up to tenfold for a new version of the company’s powered air-purifying respirators, using off-the-shelf parts like a fan used for heating and cooling seats in an F-150 truck and 3M air filters. Ford also announced a collaboration with GE Healthcare to expand production of a simplified version of GE’s ventilator. Ford said both products could be manufactured in one of its Michigan facilities.

“We have plenty of options to manufacture, between several Ford sites in Michigan and 3M and GE Healthcare manufacturing facilities,” Ford spokesman Michael Levine said. He said the automaker would share more information about the collaborations “as we learn more.”

“We have also prototyped a disposable respirator in-house,” Levine said. “Once approved by the proper health agencies, Ford will initially start at a pace equal to 1,000 disposable respirators per month but will quickly grow production as fast as possible by leveraging our network of 3D-printing partners.”

While medical groups have sounded the alarm about what they say is a critical shortage of ventilators needed for severe coronavirus cases, experts have said converting vehicle assembly lines over to producing medical equipment would be a slow process, with weeks or months needed to design and fabricate plastic-injection tool-and-die parts alone. By contrast, 3D printing can be accomplished with a design quickly created in an STL file and a spool of plastic or other material to make prints, which can be delivered in a few days.

Ford has been toying with 3D printers since around the time they were invented, having purchased its first one — supposedly the third one ever made — in 1988. Ford says it currently uses 3D printers to make two different brake parts on the Shelby Mustang GT500 and an interior component for the Chinese-market F-150. It also uses five different 3D-printed tools at its Michigan Assembly Plant near Detroit, where it makes the Ranger midsize pickup. Ford has also 3D-printed the intake manifold for Ken Block’s 1977 F-150 Hoonitruck, which it claimed was the largest metal 3D-printed functional auto part ever made, and it has developed 3D-printed knitted seat covers.

One veteran Ford engineer who is familiar with the company’s work in 3D printing, but wasn’t authorized to speak for the company, said the company has recently been using the technology to explore mass-producing parts such as intake manifolds and engine covers. Both parts are currently made from plastics-injection molds.

In addition to providing a faster path to launch production, the employee said 3D printing allows a manufacturer to layer different materials on the same print — eliminating, say, the need to glue various sound-deadening foams to the underside of an engine cover. There’s less complexity from a manufacturing and assembly perspective, with greater ability to incorporate complex small assemblies, such as a gasket, right in place rather than having it assembled by hand later. That should also ensure fewer problem down the line.

However, once fully set up, a traditional injection mold can make parts very quickly — say one engine cover every minute. By contrast, it could take 10 hours to 3D-print a single engine cover, the employee said. So depending on the complexity of a print, it might take multiple 3D printers running concurrently and around the clock to produce at scale.

“We’re just going as fast as we can,” Executive Chairman Bill Ford Jr. said in an interview this week on the “Today” show. “Nobody’s talked about the financial implications of this because this is a national emergency. And we’ll sort all of that out later. But we need to get going. We are getting going.”

A spokeswoman for GE Healthcare said the company already uses 3D printing in some of its equipment. The Chicago-based company said it has already doubled its capacity for ventilator production since the coronavirus outbreak began and plans to double it again by the end of the second quarter independent of the collaboration with Ford. GE Healthcare manufactures ventilators in Madison, Wis.

A 3M spokesman said the company was working with Ford on a waist-mounted, battery-powered blower that sends filtered air into a hood that provides respiratory protection. 3M has also doubled its output of N95 face masks to a rate of more than 1.1 billion per year, including 35 million per month in the U.S.

Related Video:

from Autoblog https://ift.tt/33Ng1zJ