Audi Repair Shop Doylestown

Call 267 279 9477 to schedule a appointment

“The development leaders of the original NSX told us not to copy what they did.” That quote from Ted Klaus, the global development leader for the NSX, explains so much about the new NSX. We’re not sure Klaus’ team could have copied the 1990s super coupe, seeing that the first NSX helped populate the world with amazing, comfortable, more practical, and much more reliable exotics. Still, Klaus’ team would have created a different vehicle than the one we have today if mimicry had been the order. That counts for the engine, too. The first NSX used a special version of the standard production engine in the Acura Legend, and the original plan for the second coming of the NSX was to spiff up a production motor from elsewhere in the Honda fold. Klaus said that by “asking ourselves the right questions,” his crew decided to develop the 3.5-liter, twin-turbo V6 mounted in the middle of the car, and a new video explores what goes into the bespoke, 500-horsepower unit.

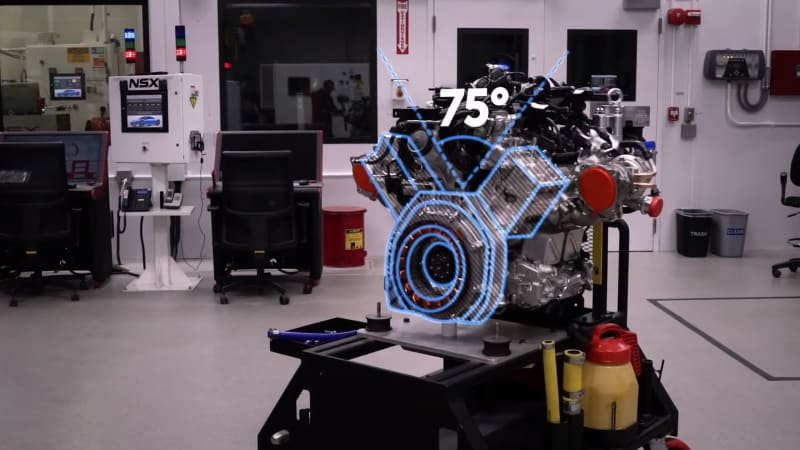

The ten-minute film is full of novel details about the power plant as well as the reasons for those details. One of the justifications for creating a new engine was that Honda knew it wanted to take the NSX racing. The 75-degree bank angle is generous enough to be able to house turbos underneath the banks, low enough so that when bolted into the chassis, the top of the heads lie below the tops of the rear tires. Even the GPS-equipped tools used to build the motor are high-tech, with items like torque wrenches tied into production software so the computer verifies each step is completed in order and to spec. One engineer breaks in each engine on a test bench before the motor is installed in the car, so instead of needing to electronically curtail a driver’s exuberance for the first few hundred miles, a dealership new NSX can be flogged as soon as the purchase papers are signed. And each engine is balanced after assembly, then again after break-in.

Craftspeople in Honda’s Anna Engine Plant in Anna, Ohio build each motor, one technician taking about five hours to build each unit. The art happens in a 4,000-square-foot engine cave carved out of the 2.2-million-square-foot facility that produces roughly 4,500 engines for other Honda vehicles every day. The video’s definitely worth a watch.

from Autoblog https://ift.tt/2vKmD59