Electric GT returns with an electric crate motor for EV conversions

https://ift.tt/2MEsMof

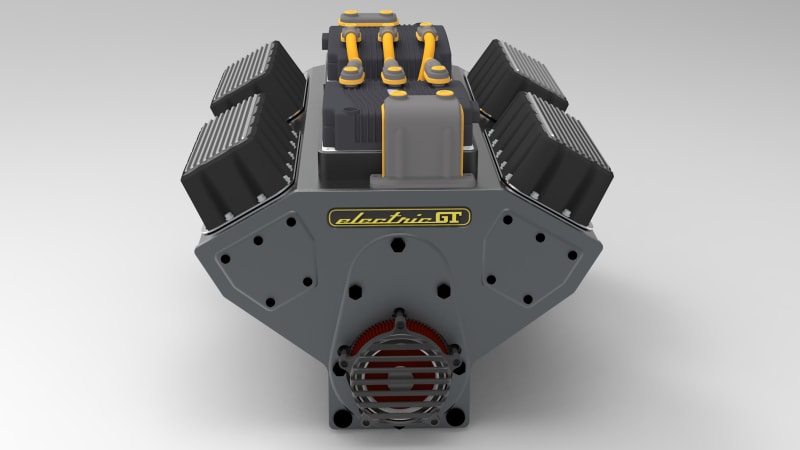

Three years ago, an outfit called Electric GT (EGT), led by Eric Hutchison, hit the green tech radar by converting a 1978 Ferrari 308 GTS to an electric car. Out went the mid-mounted 2.9-liter V8 making 280 horsepower and 181 pound-feet of torque, in went 48 lithium-ion batteries powering three AC51 HPEVS electric motors that cumulatively produced 465 hp and 330 lb-ft. The company’s relocated from San Diego to Chatsworth, California, and is back on the scopes at Green Car Reports with what it calls an Electric Crate Motor. The innovation repackages the ICE crate motor methodology into a system making EV conversions easier for the weekend enthusiast. EGT promises a plug-and-play system with “high performance and near zero maintenance,” having packaged its one- and two-motor systems into a “motor block” and peripherals that look just like an internal combustion engine.

The block includes everything necessary for the swap to electric except the batteries and the mounting bracket, meaning “motor(s), controller(s), charger(s), sensors, relays and computer systems.” EGT has already designed a number of mounting brackets, and can design others to custom specs. According to the web site, the package is “pre-engineered, pre-built, and pre-tested,” so installation takes five steps: Bolt in the block, install the wiring harness and cooling system, connect the AC and DC power leads with the OEM-level touch-safe connectors, and route the internal cooling pump to a heat exchanger. Voila, silent running. Every e-crate motor comes with an installation manual, EGT provides tech support, and auxiliaries like electric AC compressors and heaters can be optioned.

At 34 inches long, the e-crate motor is self-contained in a tidy package about five inches longer than a small-bloc V8. The standard single-motor EGT system makes 140 hp and 240 lb-ft, the dual-motor system gets 240 hp and 340 lb-ft. An AC50 unit is the default e-motor, AC51 and HyPer9 motors are available. EGT designed its system to bolt onto manual transmissions; as with the mounting brackets, the company already has a number of adapter plates and can design custom units. The only caution is ensuring the transmission and drivetrain can handle the instant torque. “Automatic transmissions are not recommended or used in EGT builds,” we’re told, “due to need for an extra hydraulic pump and the inefficiency of torque converters.”

EGT has also designed a “Tesla Swap” for buyers wanting a juicier experience. The Tesla Drive Unit with anywhere from 300 to 500 horsepower, paired with a single-speed transmission, comes in a subframe assembly ready to be bolted in, but only works with vehicles that have an independent rear suspension.

On top of a number of classic car conversions, the company recently installed the e-crate motor on Volkswagen’s Type 20 Microbus tech showcase over the summer. Now it’s doing an enthusiast-level conversion on a 1970 Toyota FJ40 Land Cruiser, and apparently has ideas for a classic Ford Bronco package. Pricing info hasn’t been sorted yet, but EGT says to expect an announcement by the end of the year.

Auto Blog

via Autoblog https://ift.tt/1afPJWx

October 14, 2019 at 10:00AM